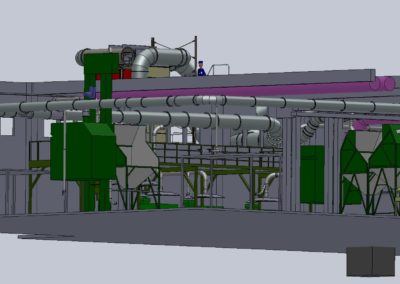

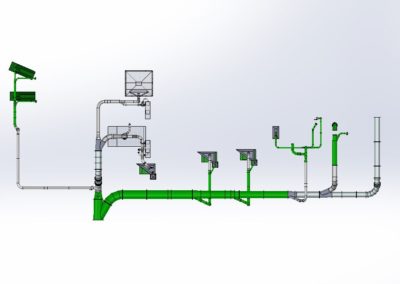

Design

Through the comprehensive product design we are uniquely planning the required workflow processes according to the emerging demands of the Customers. Beside new inspirations and concepts our Customers are encouraged to contact us with the demand of creating SMP-s for the actual problems encountered. For the design tasks we are using up-to-date Solidworks software.

Technology consulting

The key to the success of both stand-alone products and complete projects is choosing the right technology. We do have a thorough knowledge of all known and popular technologies from a theoretical and practical point of view, so we can undertake the design and specification of metal constructions and systems tailored to the needs of our Customers.

Manufacturing and installation

We are manufacturing unique items and systems and this speciality of the products defines the stages of the production process. Due to the features of the installation site or the functionality of the product the first step is always the assessment, which data is tracked from the beginning of the job. Following this we are preparing the scheme of the product which is also the basis of the quotation. In the preparatory phase of the production in certain cases there is a need for production of additional components to our machine tools. During the production the following technology can be applied: cutting, mechanic surface preparation, milling, lathe, press braking, pressing, welding

The in process quality control – on the Manufacturer and the Customer’s side as well – is an integral part of the production. We are carrying out assembly of the products as well as the the installation of the complete systems.